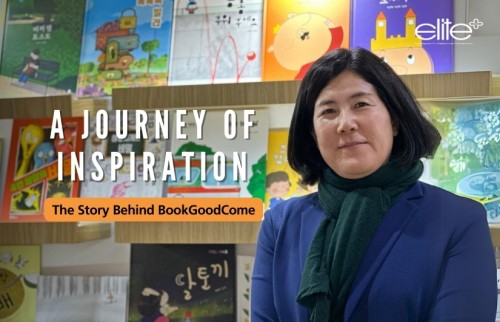

Producer of Handmade plant containers made from upcycled light-weight concrete

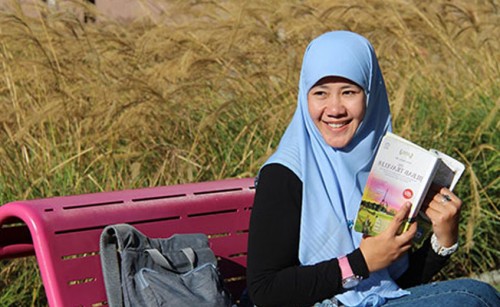

Story by Au Thitima

Translated by Pairat Temphairojana

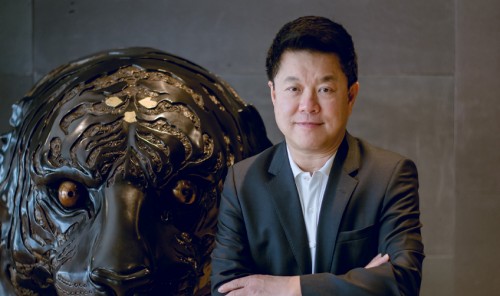

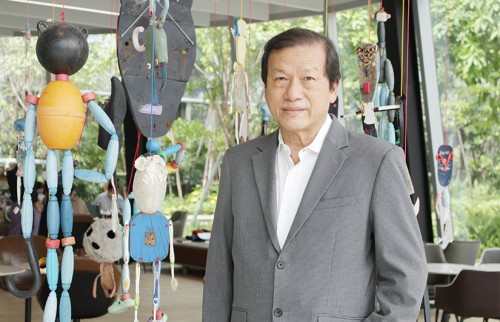

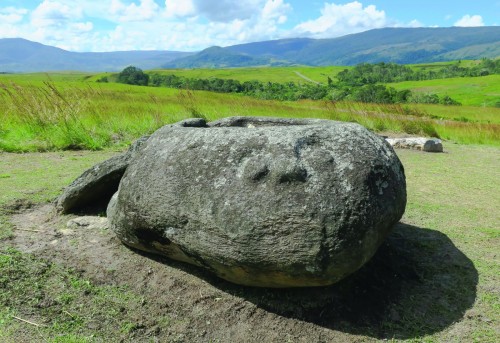

Working as a design department manager at a company producing saa paper for a decade, Kob - Rangsan Suesang decided to leave office life to sell made-to-order plant containers produced from used lightweight concrete.

Seeing an opportunity arising as there were no competitors using upcycled lightweight concrete, he developed a handmade traditional technique to create plant containers, along with a made-to-order approach for customers. His success in Thailand has now expanded to orders from overseas.

Elite+ caught up with him to ask about his background, his approach and how his products became well-known.

“I decided to leave my office job to sell plant containers, starting with second-hand Japanese houseware where I drilled holes in the bottom to convert them into plant containers. Back then, I sold my products at a lot of locations, up to eight in a single day.

“But during the late King Bhumibol Adulyadej’s passing, I stopped all my work and applied to become a volunteer to maintain royal vehicles for about six months. As I got ready to complete my maintenance work, I began to think about what to do next, and that’s when my inner voice spelled out the word ‘Stone Story’.

“I recalled a friend who was producing plant containers using lightweight concrete. So, I contacted him to ask if he was still making and selling them, and if not, whether I could pick up where he left off, but do this in my own way, and this is how I started my business.”

Employing Reduce, Reuse, Recycle concept to reduce waste

“I decided from the start that my work must be handmade and the production must be based on the 3Rs (Reduce, Reuse, Recycle) concept. I started looking for leftover light-weight concrete found at construction sites. The workers gave it all to me for free since they need to dispose of it anyway.

“Once I collected some, I drafted a design directly on to this used concrete. Then I used a machete to break the large pieces and next a chisel to shape them into containers. After that, I would immerse the containers in water to reduce the acidity of the light-weight concrete. If you do not do this, the material gathers lots of dust.

“After that, I dry the containers directly under sunlight and then smooth the surface. I use a traditional technique, so to make a small plant container requires days of work.

“As for the leftovers from the shaping process, I collect all this and have a method to dispose of it.”

Kob experimented with both the designs and process for about six months before he started selling his original product to the public.

Testing the market in Sanam Luang 2 prior to exhibiting at events

“I started selling at Sanam Luang 2 Market, but after a while, business slowed down because I wasn’t attracting new customers. So, I started to set up a booth at The Nine Center on Rama 9 Road. I would split the booth cost with a friend, about 1,000 baht each. I earned about 10,000 baht from sales. After this, I started exhibiting at various craft fairs, clean food events and zero waste events. The reception was and still is quite positive.

“People got to know me through the Baanlaesuan Fair. On the last day of the fair, the SCG HOME Experience manager approached me and said he liked my work. Following this encounter, my products are now part of the SCG HOME Experience.”

Turn to Online sales as Covid-19 Pandemic stalled public events

“Events stalled during the Covid-19 pandemic, so I turned to an online platform. I did not sell on e-commerce applications that people commonly use, but I sold primarily through Facebook.”

“As I had existing customers and because of the events I had attended, many customers knew me. I have to say I’m not good at social media or digital stuff. I never bought ads for my STONE STORY Facebook page. I was known mainly through word of mouth.

“During the Covid lockdown, I wasn’t really affected because a lot of people started growing plants at home. I was able to maintain my sales and also had foreign customers ordering my products as well.”

Made-to-order approach

“One has to understand that people here don’t really respect design rights. So, there are lots of imitators. As a person depending on my artistry, this really upsets me.”

“But I remain focused on my work and constantly remind myself to work as a designer and continue to develop my craft.

“I listen to customer’s feedback and continue developing my products to be high-quality and match my customer’s needs. I tell them that my plant containers are made-to-order, and they can order just like how they order food. Just send me the type of plants you want to grow, and I will design plant containers based on this.”

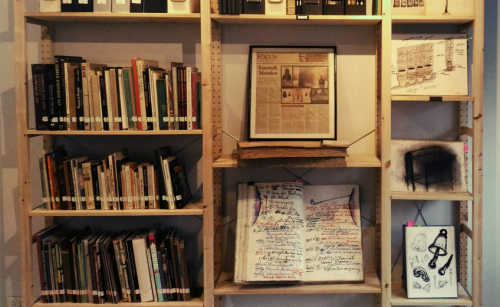

Ambition to create a gallery

“As the material costs are not high for me, most of my costs come from labor. I hire locals from the community to produce plant containers for me. So, I have helped to create jobs for locals, too.

“The income from this business has made it possible to buy a car, send my children to school and university, help my parents and to take care of my own family. The income also goes to the locals working with me. So, it’s a good balance, not too much, but enough for all.”

“My ambition now, after my children finish university, is to open a studio and gallery for my work. My hope is not to depend on events, but instead have customers visit me there.”

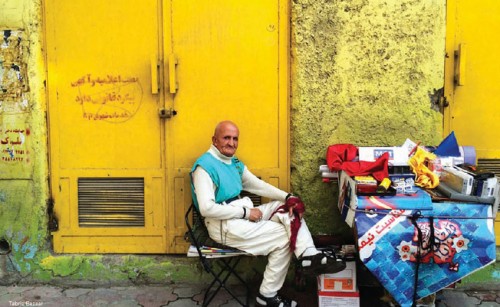

Photos courtesy of STONE STORY’s Facebook